Five Considerations for Implementing SAP Extended Warehouse Management (EWM)

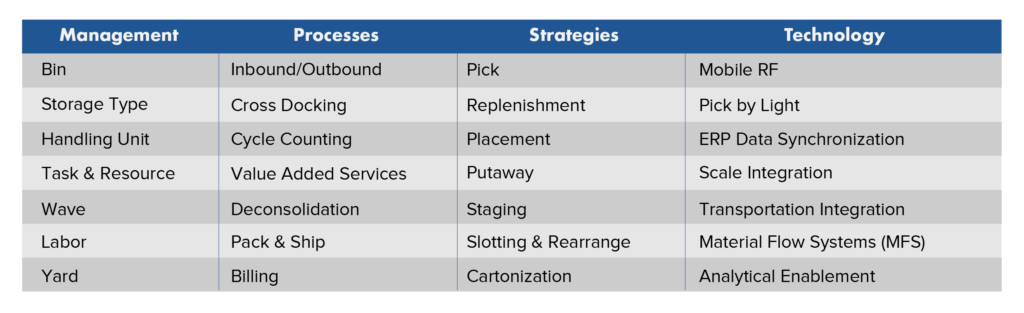

In this piece, we will discuss five considerations for implementing SAP extended warehouse management and how to realize its benefits from the following perspectives: Phasing, People, Process, Data, and Technology. SAP Extended Warehouse Management (EWM) is a highly advanced and complete solution for warehouse management. It has significant capabilities across a wide variety of processes, including:

Implementing SAP Extended Warehouse Management (EWM)

1. Phasing (Right Sizing):

As a result of the level of functionality provided by EWM, it’s critical to “Right Size” the scope of your EWM implementation. This should be done using phasing and requirements prioritization. To support phase definition, a comprehensive assessment of the organization’s warehouse management needs, future growth plans, and operational requirements is advised. Note that scope expands not just on the number of products but also on the total number of processes involved. The phases need to map to both the processes and functionality of the phase. “Right Sizing” each phase using the “crawl, walk, run” methodology will minimize risk and increase success.

2. People:

Identifying the required people resources for the implementation of the EWM module, including key business stakeholders, skilled personnel, project managers, and consultants, is critical. Not doing so results in delays and rework. Allocate resources based on their expertise and availability, ensuring adequate support throughout the entire implementation process.

3. Process:

In EWM, there is a close relationship between the physical processes and logical processes. As a result, mapping each physical step to the logical processes is essential in developing transactionally what needs to be captured in EWM. There are tradeoffs around EWM process control/verification and the amount of scanning by warehouse personnel. Identifying the critical points of verification in the warehouse management processes allows for the balancing of control and efficiency.

4. Data:

Depending on the scope of the EWM implementation, the data requirements can be extensive. First, at the item level, both the usage of the item and its physical characteristics, such as height, length, depth, weight, storage requirements, and packaged specification, must be recorded. Note that with EWM, there are additional data that need to be enhanced beyond the standard SAP material master. So, capturing and having an ongoing process for updating these data elements as products change over time must be established as part of the EWM implementation.

Second, there is the need to represent the warehouse’s physical layout within EWM. Storage types, such as freezers, hazardous material areas, pallet managed, bulk, high rack, and general, are common. Segmentation of the layout by storage sections allows for the control of which materials are permitted within a section. This is a critical capability for safely storing HAZMAT materials. Often, warehouse physical restructuring occurs to increase efficiency, align the logical model and physical layout, and improve the utilization of warehouse space. Allowing time and planning for this restructuring will help ensure on-time implementation.

There will also be a data capture/migration of inventory and warehouse data into EWM to represent the current inventory in the warehouse. It’s best practice to remove expired/obsolete inventory and then perform a physical inventory before this data migration. This process also may include a relabeling effort, so prior to relabeling, it’s important to make sure that all data elements required are on these labels, are mapped into the EWM-appropriate transaction, and can be scanned.

5. Technology:

EWM integration helps you to benefit from the tight integration of SAP S/4HANA and SAP EWM, offering you powerful functionality to increase flexibility for a best-in-class warehouse. This integration requires proper alignment of data between EWM and the SAP ERP. For example, the Bill of Materials needs to have alignment of the resource and production staging areas if picking for production is in scope for the EWM implementation. Changes in quality management inspection types may be required in the material master for EWM if quality processes are within scope.

Other technical elements of EWM include the selection of Radio Frequency (RF) mobile devices, labeling printers, scanners, and the potential integration of Automated Material Flow. The RF mobile device selection should be early enough so that comprehensive testing is possible; however, you should note that not all RF mobile devices have the same capabilities. Also, not all printers have the same capabilities for printing labels, so make sure that the specific make and model of the printer can print the labels required. Further, automated flow systems will have additional communication requirements and will need an additional integration effort.

Moving Forward

With any SAP EWM implementation, there are several critical considerations – from budgeting to resource management, to ensuring user adoption. At Clarkston, we have the right combination of industry and functional expertise to help your organization, no matter where you are on your SAP journey. If you are looking for guidance on EWM implementation or other SAP solutions to meet your business’s needs, reach out to our team today.