Detecting Early ERP Project Risk Signals

Echo vs. Impact

Leaders who rely solely on formal reporting and project calendars are often late to recognize and respond to risk during an ERP implementation. Effective organizations are those that pay attention to behavioral and structural indicators before schedules slip, integrations fail, or downstream testing degrades.

ERP project risk rarely begins with missed milestones or red status reports; it develops earlier and is revealed through changes in how teams communicate, how they make commitments, and how decisions are made across business and technology stakeholders.

Early signals are the echo of future failure, while missed deadlines, poor data quality, failed testing cycles, and disrupted cutovers are the impact. When early indicators are ignored, risk accumulates quietly until it surfaces in delivery metrics, often when recovery options are constrained and trade-offs become unavoidable. Detecting early ERP project risks requires understanding which signals tend to appear first and how routine ERP project behaviors reveal underlying issues.

Clarkston recommends a tiered risk framework based on observed warning signs across ERP programs. The tiers reflect patterns commonly seen in ERP implementations that later experience delivery challenges, while the examples and guidance draw from practical ERP project leadership experience. Together, they provide a clear, actionable perspective on how ERP risk develops and how it can be identified early, before it appears in formal status reporting.

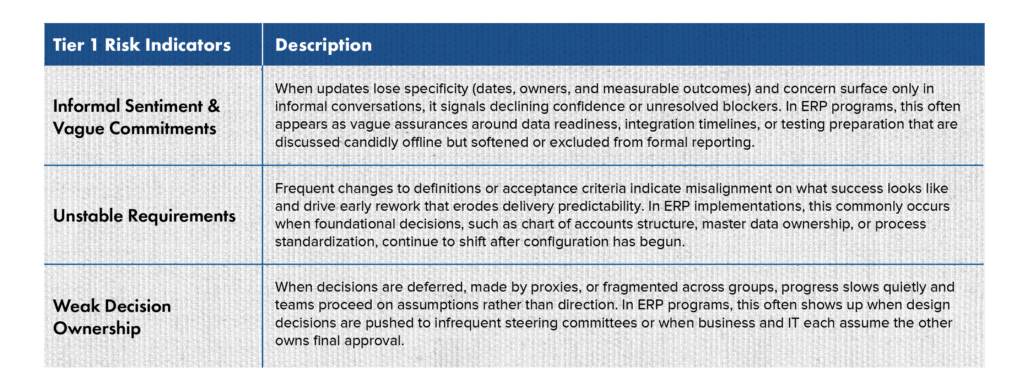

Tier 1: Earliest and Most Dangerous Signals (Act Immediately)

Tier 1 signals are predictive, behavioral, and quiet. They appear early, often quietly, and always cascade into later failures if left unaddressed. When Tier 1 is present, the project is already at risk, even if all formal indicators remain green.

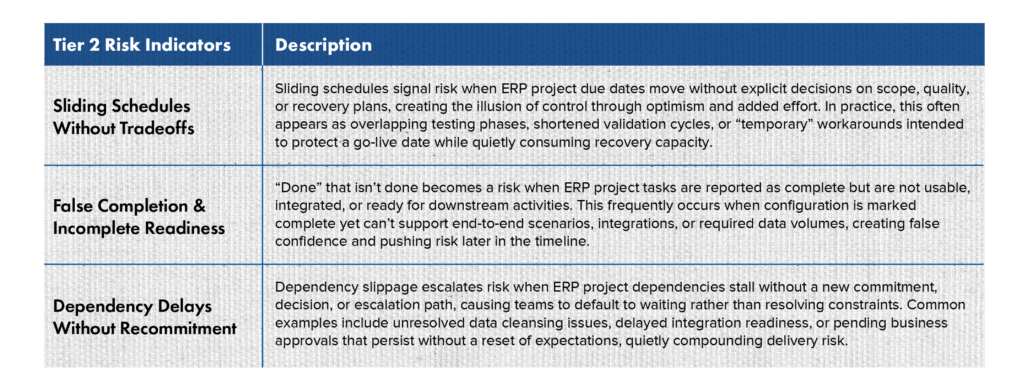

Tier 2: Structural Breakdown (Still Recoverable)

Tier 2 signals are visible but often normalized or explained away. At this stage, recovery is still possible, but only if the signals are acknowledged and addressed. Tier 2 signals indicate that the project is compensating for unresolved issues rather than addressing them directly.

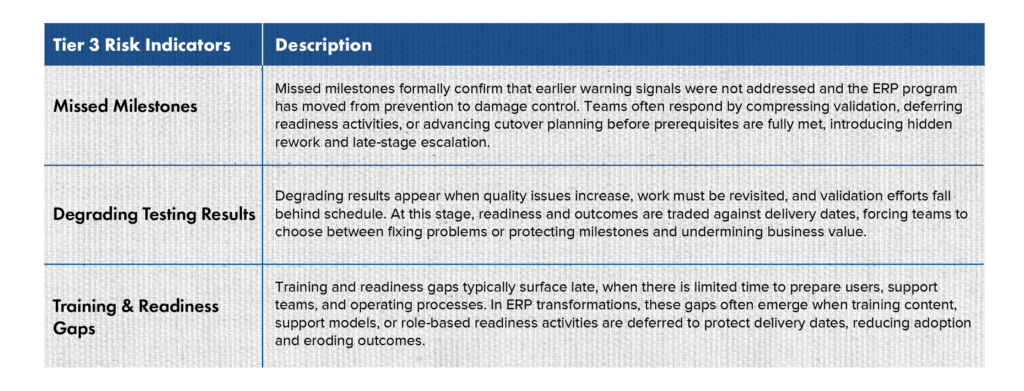

Tier 3: Lagging Confirmation Signals (Harder to Fix)

Tier 3 signals confirm issues that have been developing for weeks or months. When these indicators appear, the project has moved from risk prevention to damage control, and recovery requires explicit tradeoffs. Tier 3 signals rarely appear in isolation; they are the visible outcome of earlier Tier 1 and Tier 2 signals that went unaddressed.

Looking Ahead

Early risk detection is about recognizing the signals that appear before outcomes are locked in. Across ERP programs, Clarkston has repeatedly observed these patterns and intervened early, often well before traditional metrics indicated risk, allowing teams to reset expectations, resolve constraints, and preserve delivery options.

Subscribe to Clarkston's Insights