Supply Chain Resilience: The New Imperative for the Chief Supply Chain Officer

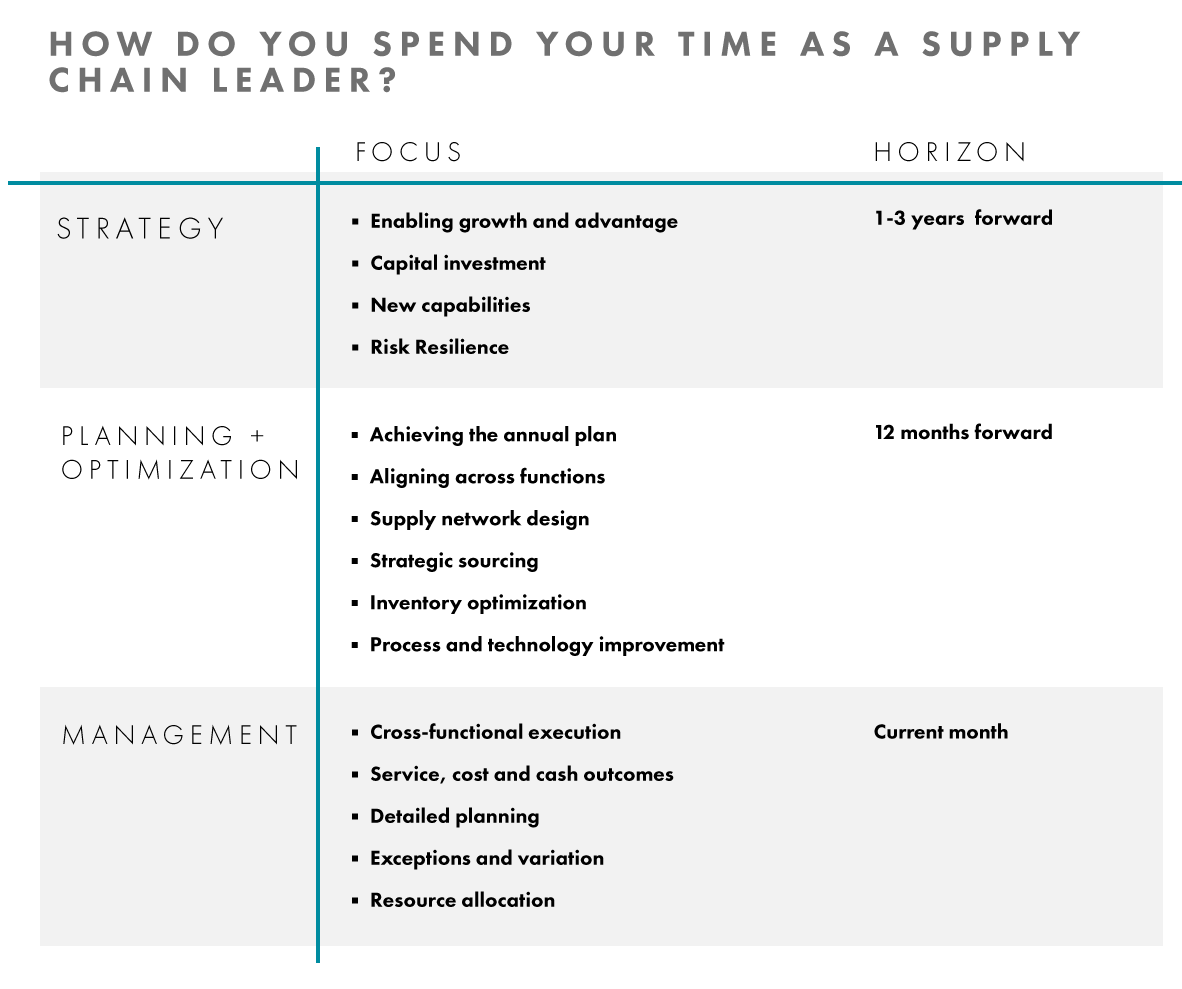

Among the many things that the Coronavirus pandemic has laid bare is that our supply chains are not resilient. They were not deliberately designed to resist disruptions and recover quickly. Moving forward we need to rethink what good looks like. The most admired will position their business to manage through whatever may come. That creates a new imperative for supply chain leaders to be more strategic and strike a better balance between day-to-day management and longer-term planning and optimization in order to have supply chain resilience within their businesses.

Many supply chain leaders have aspired to being influential with the C-suite as strategists and catalysts for growth. But that is easier said than done. For those that have risen through the ranks of planning, purchasing, manufacturing, and distribution it is all too easy to be seduced by management. Like firefighters we throw ourselves at each day’s crisis, find innovative solutions, and reap praise and recognition for saving the day. It’s ironic that the more time supply chain leaders spend engaged in managing the day-to-day, the more we take away from our ability to have an enduring impact on overall business success.

Clarkston’s experience working with consumer products and life science companies suggests that organizations fail to achieve ambitious transformations when they get caught in an “execution trap” when execution is not sufficiently balanced by strategy (Bridging the Strategy to Execution Gap). We find that execution may outweigh strategy when time is not explicitly set aside for planning and optimization; when a healthy bias for action is not supported by facts and analysis; and when knowledge is overly concentrated in a few individuals.

Here are three practical recommendations that supply chain leaders should consider to avoid the execution trap as you pursue strategies for more resilient supply chains.

Make a supply chain resilience strategy, planning and optimization part of the annual planning process:

Many companies calendar strategic activities at the end of the fiscal year culminating in an operating plan for the coming year. We recommend that supply chain leaders set aside time in advance of volume and financial planning to reassess how the supply network aligns to evolving commercial strategy, market conditions, and the company’s preference for risk. Put it on the calendar and don’t let management of the current period crowd it out.

Develop advanced analytical capabilities:

There are a couple analytical capabilities that are particularly relevant to supply chain risk management. Optimization models (sometimes called “digital twins”) provide the quantitative ability to assess explicit tradeoffs between service, cost, and assets. Once the models are developed, it is relatively straightforward to assess disruption scenarios and sensitivity analyses to understand your network’s tipping points. A second analytical capability which is increasingly impressive is data science, using sophisticated modeling to predict future events or discover patterns. When the next disruption upends your supply chain, you would be well served to have established data science capabilities available to reduce the fog of uncertainty.

Integrate strategy into sales & operations planning (S&OP):

The most common place for strategy to unravel is at the seams of functional boundaries. Businesses that have embraced S&OP have created highly productive cross-functional forums for mid to long term planning. Make strategy an agenda item in each of the product, demand, and supply reviews to ensure that each function is operating in accordance with strategy, to monitor key initiatives, and to identify when a strategy change might make sense. Also, make sure that your S&OP process is one which encourages risks to be voiced openly. One inspirational supply chain leader told me that he never held it against someone for making a risk visible to the S&OP team, but he had terminated three people for hiding risks.

As companies pursue supply chain resilience there will certainly be battles between those with a shorter-term focus and those with the foresight to look farther down the road. It is a fitting challenge for supply chain leaders who have aspired to be influential in the C-suite–garner investment in a higher cost supply network in favor of one that is more resilient and positioned to gain advantage when competitors falter.