Preparing for the BIOSECURE Act and Its Impact on Your Supply Chain

With the pending BIOSECURE Act currently receiving bipartisan support in the U.S. Congress, it becomes increasingly important for all U.S., U.K., and European companies – especially in the life sciences industry – to be aware of where the products within their supply chains originate. This not only refers to the product itself but also to the technology and machinery used to create and process these products. Below, we share considerations for preparing for the BIOSECURE Act and its potential impact on your life sciences supply chain.

What is the BIOSECURE Act?

The BIOSECURE Act is meant to ensure improved competitiveness within the biopharmaceutical industry while also protecting national security. Companies like AstraZeneca, Amgen, Pfizer, and Eli Lilly, which are based in the U.S., U.K., and Europe, would be prohibited from conducting business with major drug development and contract manufacturing partners, such as WuXi, AppTec, BGI Group, MGI, and Complete Genetics (entities specifically named in the legislation) as well as other potential biotechnology companies of concern (e.g., companies with ties to the governments of China, Russia, North Korea, or Iran).

If enacted, companies would be forced to choose between receiving funding from the U.S. government or having contracts with those named partner companies. Ultimately, it’s believed that companies will choose to discontinue their relationships. According to a Biocentury survey, 90% of drug manufacturers surveyed said their number one concern is a lack of biopharma research and manufacturing capacity. If the bill becomes law, this change will impact their research pipeline and cause a slow-down in clinical trials, drug approval, and drug availability.

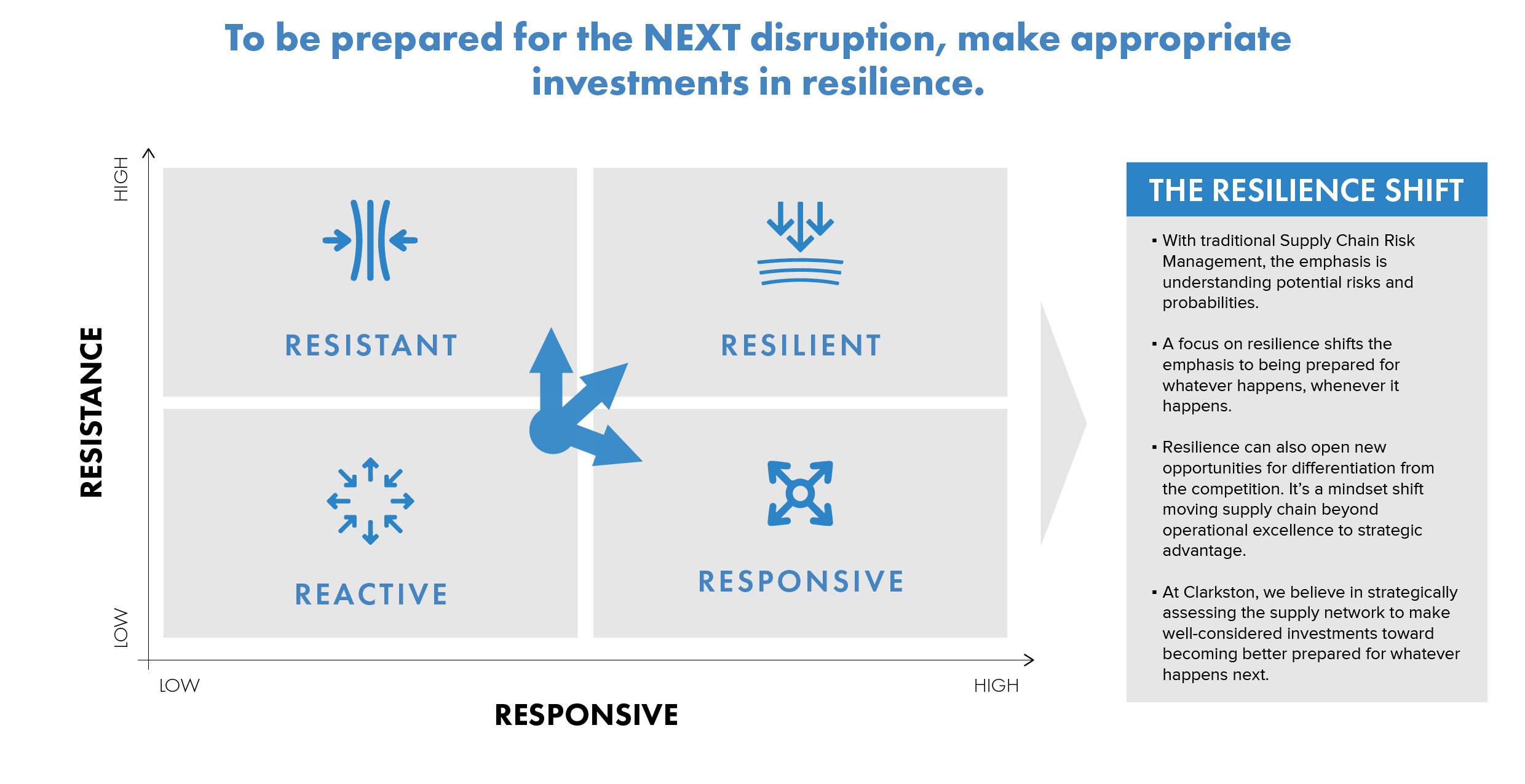

While the Act is focused on the biopharmaceutical industry, all supply chain leaders, CEOs, and boards of directors should be vigilant in assessing their organization’s risk and resiliency strategy. Today, it’s important for supply chains, especially in strategic technologies, to evaluate how the undergoing geopolitical changes will impact their ability to be reliable and resilient. This will require a change in business strategy, especially for those who have been primarily cost focused.

Improving Cost and Service in a Global Supply Chain

Global supply chains have been in place for years; however, the current globalization strategy began in earnest in the 1990s, led by Michael Porter’s philosophy on business strategy, which argued that companies either choose a cost advantage or a differentiation advantage strategy. During this same period, an early book focused on the field of supply chain was published, Logistics and Supply Chain Management by Martin Christopher, who makes the promise that supply chain management would allow an improvement in both cost and service.

Porter and Christoper’s teachings have driven the way companies view business and supply chain strategies, and these concepts remain highly prevalent today. The most typical strategy is that companies want high service/delivery performance, however, they’re constrained by high costs and/or high levels of materials tied up in working capital. This has resulted in the famous “cutting of inventory” to meet the financial target and having the opposite effect on service.

Traditionally, it has fallen solely on the supply chain to solve this challenge. However, as supply chain leaders know, balancing the opposing objectives of various departments, including sales, manufacturing, and finance, is impossible. In short, it’s impossible to deliver higher service levels and lower costs while freeing up cash, and supply chain leaders face the challenge of how to satisfy all the conflicting objectives. Often, this leads to not achieving anything because without knowing the priority – cost, cash, or service – they fail to focus on anything.

Preparing for the BIOSECURE Act

As the COVID-19 pandemic started, it became immediately apparent companies couldn’t be everything to everyone. Their ability to achieve these multipronged business strategies became impossible. Boards of directors, CEOs, and business and supply chain leaders had to choose one area on which to focus: service, cost, or cash. Additionally, it became clear how interconnected both the supply chain and business strategies were in being able to meet customer needs and expectations along with the business goals. Furthermore, it identified significant gaps in how organizations developed and stress tested their risk and resiliency strategy.

Currently, organizations have adjusted to a new way of conducting business. For many, business has returned to normal – however, normal is different. Businesses have witnessed the fragile nature of a global supply chain. The challenge now is what will they do to ensure they’re prepared for a future global disruption?

The BIOSECURE Act: Prioritizing a Risk and Resiliency Strategy

This brings us back to the pending BIOSECURE Act. What are companies doing today to reduce their risk and to ensure resiliency?

Align on Strategy: Organizations must return to a discussion about strategy. The strategy or strategies that a company began with previously may not or cannot work in the complexity of today. There are many ways for a company to differentiate and build a competitive edge. This requires companies to make hard choices – a company can’t have everything. Organizations need to intentionally determine what their investments in capabilities to resist and respond to disruptions should be. These decisions will differ by product type and tier, as well as the size and share of the market the company holds.

As supply chains define the cost and capital employed, supply chains must be a part of the strategic discussion of what a company’s business strategy will be focused on. To achieve this, a business must determine what value they will provide. Will they be focused on being a product leader, a service leader, or a cost leader? It’s not possible to be everything to everyone; therefore, a company must choosewhat market they are going to compete in.

Integrate Your Strategy: Once the strategy is aligned, it’s important to ensure all supply chain strategies are integrated. One of the first that should be assessed is the supplier selection methodology. It’s important to ensure the right one is chosen and not just an opportunistic pursuit for the lowest cost. If this isn’t considered, the challenge arises when the lowest cost provider chosen faces disruption. This could be a quality event, a spike in demand, or restriction in raw materials…or any other multitude of disruptive events.

Supplier selection is just one of the operational supply chain tactics that should align with a coherent company approach to resilience. There are strategic network design considerations, as well as organizational abilities that also should be aligned with the company’s stated strategies.

Establish a Balance: Additionally, a company must establish a balance between the seemingly contradictory objectives and one that creates a holistic operating model. This alignment can be achieved by leveraging financial metrics with the chosen strategy. As an example, a product leader requires a higher capital employed and has a higher cost (R&D & marketing), but by selling unique products in high-end niches, they can command a higher premium from customers who will compensate for this. The operational excellence leader has the lower cost and minimal EBIT (to guarantee the lowest price in the market) but compensates for that by working with less capital employed.

Why is this important? To an investor, the ROCE (Return on Capital Employed) principle tells them it’s okay for a product leader to have a higher capital employed if the company generates higher EBIT, or it’s okay for the OPEX company to have a lower EBIT if they require less capital employed. To an investor, if it leads to the same ROCE, it doesn’t matter how it’s obtained. Using a financially aligned method, it becomes possible for establishing, evaluating, and measuring the strategies’ success. A business can map the established value proposition to the needs of the business and supply chain, and from there, ask and model the changes to its network or supply chain design and simulate the impact these changes will have on ROCE.

Using this technique can seem overwhelming, however, we believe this is a more balanced way of thinking and acting and will bring more value in the end. This is a journey, but one that brings businesses increased value for their shareholders.

The Impact of the BIOSECURE Act on Supply Chain Resiliency

As recent experiences have shown, supply chains are easily impacted by change. Whether those are natural, such as COVID-19 or hurricanes; manmade, such as the Baltimore bridge collapse or labor strike; or geopolitical, such as the BIOSECURE Act or other trade restrictions, it’s important for organizations to be prepared. As such, business leaders can take proactive steps, such as recognizing the signs, diversifying early, and developing contingency plans.

Organizations must adapt to geopolitical uncertainties, prioritize resilience, and consider the broader context related to their overall business strategy beyond just cost savings and lower inventory. For further guidance on preparing for the BIOSECURE Act or a more resilient supply chain, reach out to our team today.