Six Best Practices for Managing Product Shortages with SAP aATP

In this piece, we outline six best practices for managing product shortages with SAP aATP in order to optimally automate product allocation.

In the consumer products industry, the purpose of product allocation is to ensure that enough goods are on hand when and where they are required, so that customers can buy what they want, and the business can optimize profit. Allocation rules also help CPG companies to have the right protocols to ensure they maximize inventory in the right way when they face shortages. The challenges of supply interruption have been relentless over the last five years, with causes ranging from the global pandemic to closed shipping lanes, wars, and port strikes. It’s a simple reality that supply chain interruptions are going to occur. So, given that fact, the question is: how can a consumer product company plan in advance to best allocate products during a shortage?

Below, we discuss six best practices that need to be considered when using technology to implement automated product allocation. This functionality within the SAP ERP solution comes from the deployment of Advanced Available-to-Promise (aATP). SAP aATP is a business function in SAP S/4HANA that provides a response to order fulfillment requests in Sales and Production Planning. An order fulfillment request consists of the required material, plant, requested quantity, and material availability date. The response to the request is based on the current stock situation and any future, anticipated shortage or planned stock receipts and considers concurrent orders across channels. When product becomes available, a systemic solution kicks in to prioritize the backorders for fulfillment based upon a defined criterion.

Overview

To optimally implement this solution, the following best practices for managing product shortages with SAP aATP need to be applied:

- Establish a robust demand planning and trade promotion planning process.

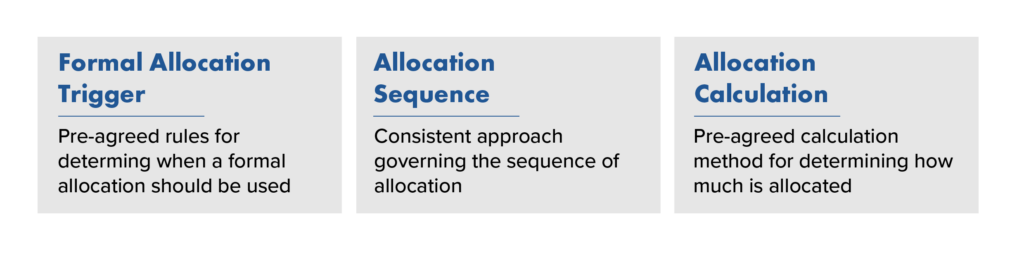

- Create and maintain a collaborative and clearly defined rule set with buy-in across all critical stakeholders such as sales, marketing, finance, operations, and supply chain. These rules define the allocation trigger point, sequence, and calculation.

- Achieve a rigorous and continuous master data governing process with supply, production, and distribution constraints being clearly understood. These constraints include shelf life, replenishment lead-times, production capacity, and transportation limitations.

- Identify and maintain product substitution options and interrelated products.

- Leverage real-time sales data to evaluate and reevaluate allocation levels.

- Include scenario planning and alternative supply options in the supply chain operating strategy.

A Deeper Look at These Best Practices

1. Demand Planning and Trade Promotion Planning

The first practice is establishing a robust demand planning and trade promotion planning process, with a sound constrained Integrated Business Planning (IBP) process. Understanding anticipated demand is the cornerstone of making sure that enough goods are on hand when and where they’re required. This means there is a consensus process established for sales forecast at a sufficient level so that customer, location, and required products can be estimated for the future horizon. Since, in the consumer products industry, advertising and special promotion can make substantial changes in demand, trade promotion activities and tactics must also be considered.

2. Defined Rule Set

The second practice is one of the most challenging ones as it involves not only forming a consensus but also educating the stakeholders on the rules and logic that represent how allocations will occur. This practice is to have a collaborative and clearly defined rule set created and maintained with buy in across all critical stakeholders. It’s a critical change management activity to achieve as the rules are only effective if the organization accepts them.

One of the hardest parts of any aATP project is getting rules on paper and ensuring they are agreed upon by the business. These rules need to be able to balance across multiple objectives, including customer priority, market growth plans, and sales revenue plans. Rules must be able to be written and included in a system; if a “rule” cannot be written and is full of exceptions, it cannot be programable into a system. Best-in-class companies make such rules simple, avoid exceptions and complexities, and build the right governance to minimize ongoing changes.

3. Master Data Governance

The third practice is to establish a rigorous and continuous master data governing process with supply, production, and distribution constraints clearly understood. These constraints include shelf life, replenishment lead-times, production capacity, and transportation limitations. Product expiration dates are a critical factor for inventory allocation, and items with the shortest shelf life should be allocated first. Sending products with a shorter shelf life to locations with high sales volume keeps these items moving and limits obsolescence. Having accurate replenishment lead-times and adjusting them when delivery times have extended is essential to having a future view of supply. By knowing constraints, such as replenishment lead-times, safety stock can be used to guard against demand fluctuations and lead-time delays. Having inventory close to where it’s needed reduces lead-times and can increase customer satisfaction. In order to have a feasible allocation plan, key constraints must be known.

4. Product Substitution

The fourth practice is to understand and maintain product substitution options and interrelated products. Product substitution can help mitigate supply chain disruptions, but it may not be effective without other strategies like dual sourcing. In the case of product substitution, demand is pushed from one product to another, which requires that the supply be flexible. To support this demand, alternative sourcing may need to be deployed. SAP aATP can recommend stock transport orders (STOs) when the right product is in the wrong distribution center.

In the consumer products industry, interrelated product demand is common. Whether its toys related to a movie release or food products sold together, understanding how one product drives the demand for another allows for a more holistic and accurate view of how demand is impacted across products. Some global consumer product companies use postponement strategies to delay “localization” (i.e., labels) to the product and have greater inventory to be allocated globally. In this case, companies may have the same product but one may have instructions and labels in English and another in French… but it’s still the same product. To be effective, this strategy requires understanding product interrelationships and transportation lead-time constraints.

5. Sales Data

The fifth practice is the leveraging of real-time sales data to evaluate and reevaluate allocation levels. This includes actual orders, customer inventory levels, and POS data. Real-time data analysis provides critical insight into demand trends, enabling more informed inventory allocation decisions. This on-demand insight helps prevent distribution centers from being short-stocked or having a surplus, resulting in more strategic replenishment. Inventory allocation is a continual process that requires constant response to changing sales data. As customer demand shifts, the inventory allocation strategy must balance to meet demand while avoiding overstock. Utilizing real-time sales data lets companies have visibility into how much stock they should allocate to which location based on demand.

6. Scenario Planning and Alternative Supply Options

The sixth practice is to implement scenario planning and the development of alternative supply options as part of the supply chain operating strategy. A resilient supply chain does not happen by accident; it’s the result of proactive planning and predeveloped supply relationships. Anticipating disruptive scenarios in advance allows for reducing risk and effective mitigation.

To be cost-effective, alternative supply relationships need to be established before disruptive events occur. This may mean that source demand is split amongst alternative suppliers to maintain supply capacity.

The benefits of automating allocations go beyond being able to respond to supply chain shortages. Additional benefits include:

- Being able to specify the volume that each market is going to receive during constrained horizon

- Increasing profitability by allocating inventory in times of shortages according to profitability profiles or customer and products

- Giving transparency to markets on what they can plan to sell

- Monitoring if the markets commit to order more than their allocation

- Allowing time to solve the reasons behind the constraint

- Enabling supply and markets to rebuild stocks

- Prioritizing where available stock is sold base of market growth and financial goals

- Minimizing ‘noise’ / fiscal impact of any constraint

Moving Forward

SAP Advanced Available-to-Promise (aATP) builds upon the core features of considering inventory allocation across multiple locations (warehouses, manufacturing plants) and even incorporates capacity checks (labor, machines), extending these capabilities with dynamic simulations to offer real-time availability checks and suggesting alternative plants or production schedules if needed. There are new capabilities that consider only those demands where there was a change in either supply, demand, or master data, thus signifying improving efficiency and processing time.

While many of these new aATP capabilities greatly enhance the effectiveness of managing product allocation during shortages, the establishment of a strong IBP process and the human side of setting up rules, maintaining data, and instilling change management are all essential for success.

With any SAP implementation, there are a number of critical considerations – from budgeting to resource management to ensuring user adoption. At Clarkston, we have the right combination of industry and functional expertise to help your organization, no matter where you are on your SAP journey. If you are looking for guidance on an aATP implementation or other SAP solutions to meet your business’s needs, reach out to our team today.