Three Fundamentals to Reducing Your Supply Chain’s Complexity

As anyone who has coached youth baseball can tell you, the first thing they work on with players at the start of a new season – whether it’s a T-ball league, where kids are playing baseball for the first time, or experienced players returning for another season – is fundamentals. The kids enter a new season with big dreams of hitting home runs and turning double plays. Still, the things they must work on first are the fundamentals – basic throwing, catching, and hitting for contact, knowing that if players are unable to do the basics well, they will not be hitting many home runs or turning any double plays.

The same is true for your supply chain. If you haven’t established the fundamentals as the baseline for how your supply chain operates, it will be awfully hard to hit that home run with your customers and clients. In this piece, we’ll discuss the key fundamentals for reducing your supply chain’s complexity: establishing time fences in planning, ensuring master data is complete and accurate, and treating exceptions as exceptions.

Three Fundamentals to Reducing Your Supply Chain’s Complexity

1. Establish Planning Time Fences

I’ve worked for a couple of companies where forecasts were still being adjusted well into the new month, and the sales team would consistently request to put priority customers to the front of the line. Predictably, this ever-changing forecast, and requests for orders to be reprioritized, rolled downhill to the supply plan, where the schedule to the plant floor would change daily, leaving the manufacturing team frustrated as they would lose production time every day waiting for the schedule to be finalized. This caused daily execution issues related to how to staff their lines and which products to make. The Customer Service team and customers would get frustrated, as product availability dates would constantly be shifting because of the ever-changing production schedule.

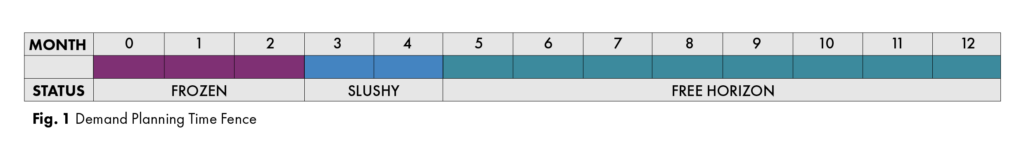

If your business is going to hit a home run with its customers, it will need to bring reliable predictions to product availability. It starts with establishing planning time fences, both for demand and supply. From a demand perspective, the frozen horizon (Fig. 1) may vary depending on how product is sourced but should be a minimum of three months (current +2 future months). This gives visibility and certainty to the downstream operations like Sourcing, Production Planning, and Manufacturing Operations on what they need to buy, when it needs to be scheduled for production, and how much labor will be needed to meet the demand.

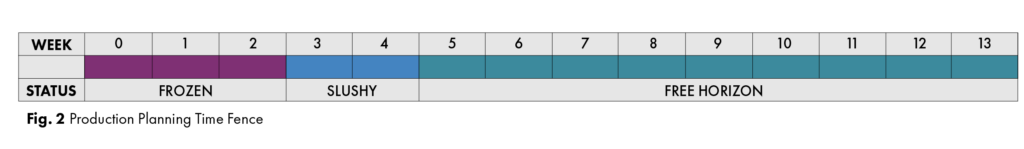

From a production planning perspective (Fig. 2), the schedule should be locked, with an established escalation process to consider exceptions to the locked schedule. Again, the frozen horizon may vary, but should be a minimum of three weeks (current +2 future weeks), and it’s recommended that an escalation process be put in place to govern when a schedule break-in may occur.

2. Master Data Governance and Maintenance

Another area where it’s critical for companies to get back to basics is in the management and governance of their data. If data is incomplete or inaccurate, it affects the ability to implement meaningful KPIs, as well as hinders the company’s ability to segment its product and customer portfolios effectively. If a company can’t trust the data available, it leads to siloing of data and metrics, where departments are making decisions based on their own data, leading to the unsynchronized operation of the business. Time is then spent in meetings either reconciling data or arguing about whose data is the correct version instead of looking forward and planning how the company can continue to grow.

A company that is unable to effectively segment its product and customer portfolios runs the risk of missing out on shifting trends in the marketplace or the ability to identify a segment that is underserved or ripe for disruption from a new product or service. If a company can’t trust the data being generated for corporate KPIs, then there’s little confidence in the actual direction of the company.

To avoid these pitfalls, companies should establish a master data governance team. Depending on the size of the company, this can be a single individual up to a full team of many individuals that’s a subset of a department or even comprise their own department. They’re given the authority to establish the rules for master data governance and are accountable for completeness and accuracy. A master data team will enable a company to have confidence in its data, as there’s a team in place who is accountable for the completeness and accuracy of corporate data.

3. Treat Exceptions as Exceptions

Companies risk losing flexibility and tend to see increased disruption within their operations when they fail to treat exceptions as one-off occurrences that do not and will not occur frequently enough to warrant a process change. It’s recommended to have an exception management process in place, providing a structured approach to managing the exception.

Having a robust exception management process in place will help provide the structure needed to manage exceptions as they occur, preserving the flexibility within your processes that govern the majority of the day-to-day operations and minimizing the disruption the exception causes to the business process overall. Additionally, an exception management process will help identify any gaps in processes that led to the exception, providing a path toward potentially preventing the occurrence of the exception in the future.

The exception management process should also include a mode for escalation that outlines when an issue needs to be escalated, what boundaries the functional area has in resolving the escalation, and to whom further escalation should be made. An example of a common exception would be a request to change the schedule within the frozen time horizon. A typical chain of escalation to determine whether a break into the schedule is to be made or not might look like this:

Depending on the severity of the issue and the decision-making authority in place, the escalation may stop at the Supply Planner or could move to needing to be resolved by senior management.

Executing the Fundamentals

In a world of complex supply chains and business processes, it’s the simplicity of executing the fundamentals for planning, data management, and exception management that will help your business thrive and keep your customers satisfied.

If you’re looking for more guidance on executing the fundamentals and reducing the complexity of your supply chain, connect with our supply chain experts today.

Contributions from Ryan Mueller